Maintaining and Storing your Titespot® Angle Head

Titespot® High Pressure Coolant Driven Angle Heads are powered hydraulically by a positive displacement ball piston motor. With proper attention to coolant cleanliness and angle head conditioning prior to storage, they require minimum maintenance.

Important! After Using Your Titespot® Angle Head

When a tool is not going to be used for an extended period of time or is being returned for repair it is important that coolant is not left inside the tool to dry up, harden or even corrode the tool. The instructions below give the procedure to prevent this mode of failure, which is the most common maintenance issue we observe.

If the angle head is to be taken out of service in excess of 48 hours, it is essential to flush and condition the tool as described below. Failure to follow this procedure may result in residual coolant coagulation rendering the tool inoperable.

A. Blow high pressure filtered air through the retention knob, until all residual coolant is flushed from the tool.

B. Squirt an oil (WD-40, or automatic transmission fluid or similar) into the tool through the retention knob.

C. Blow air through the retention knob until oil is observed exiting the tool around the spindle bearing.

D. As with any tool holder, coat the external surface with oil and store in a clean, dry place.

How to Maximize Motor Life

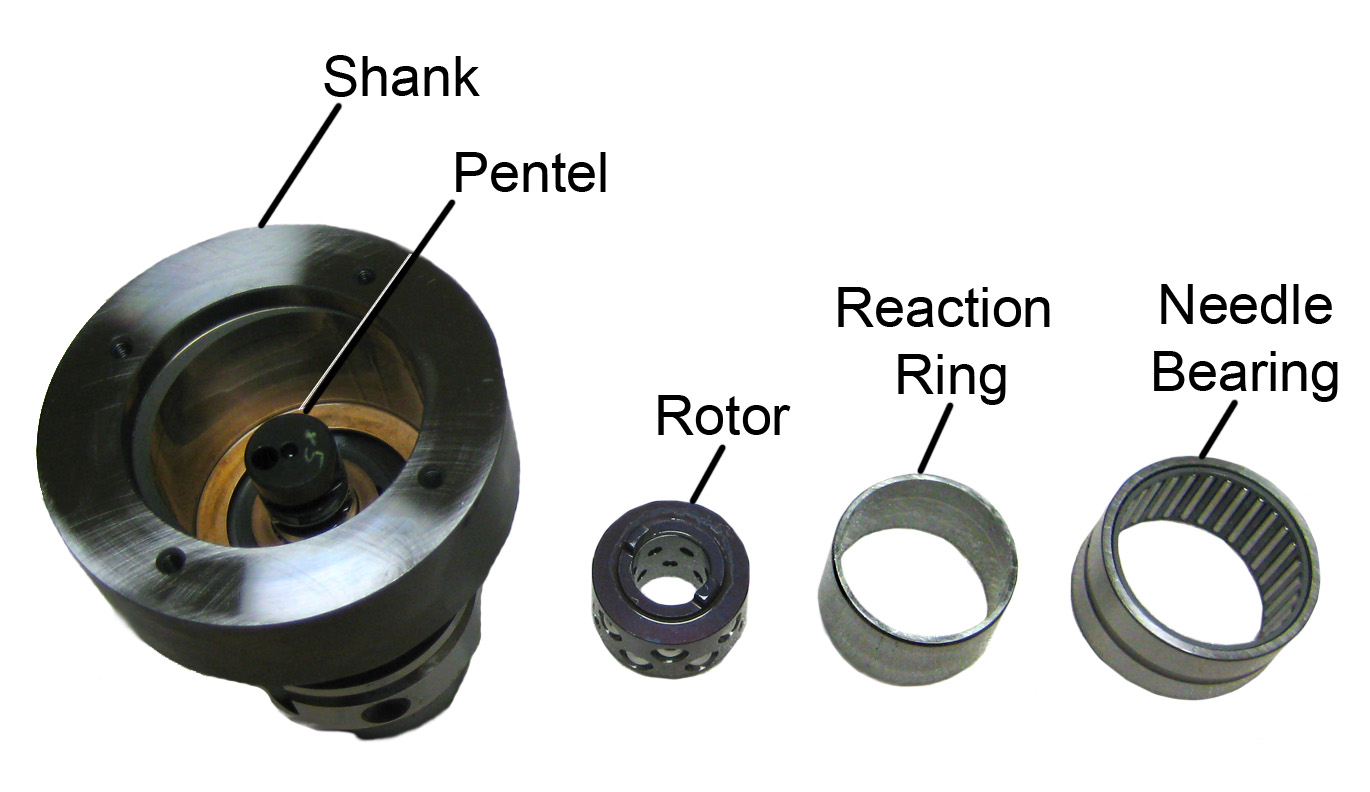

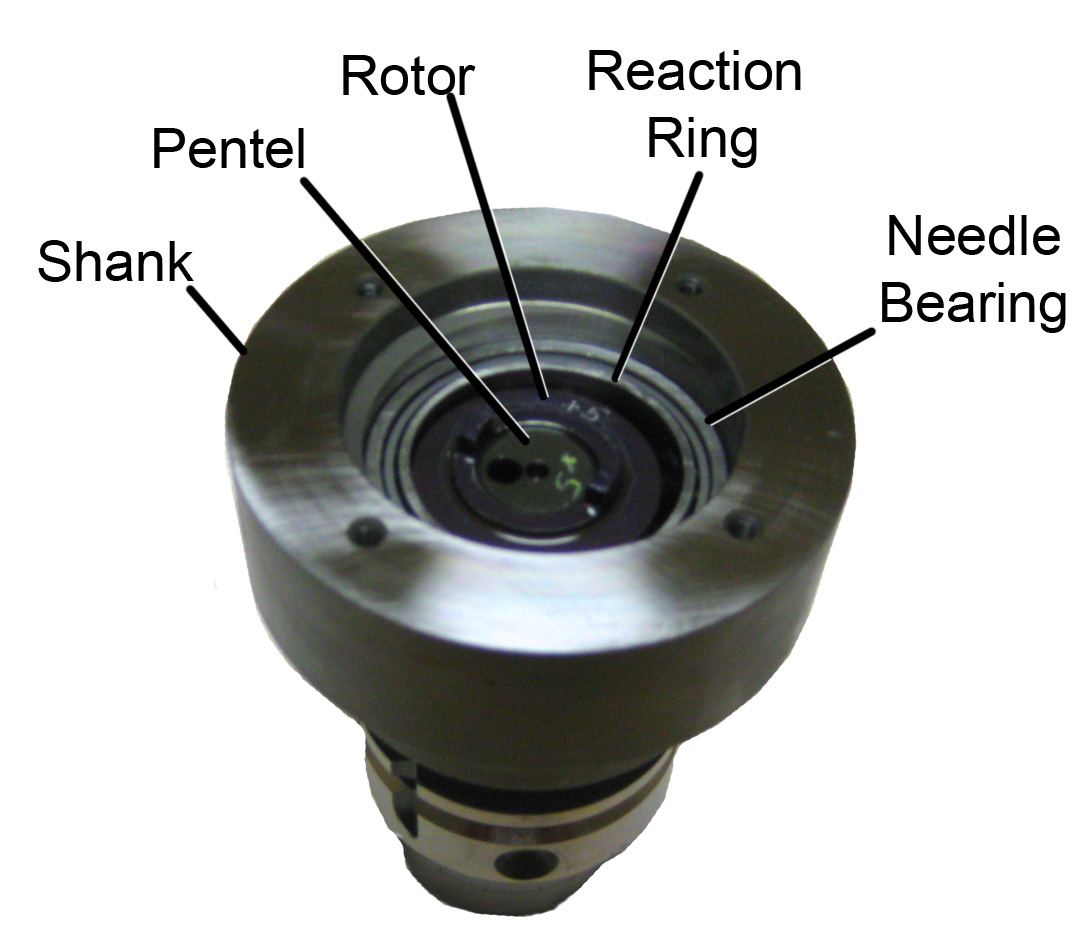

The reaction ring tends to be the first part to wear.

It is inside the shank surrounding the motor and is the inner race of the large needle bearing. The ball pistons in the motor’s rotor push against this ring as it slowly rotates.

The ring is mounted in such a way that the balls do not ride on it symmetrically. You can extend the life of the motor by tracking hours and flipping the ring after approximately 250 hours of use. Some applications may benefit from more or less hours depending on such factors as coolant cleanliness, the amount of coolant pressure and the severity of the application. The reaction ring can have a ball track much like a bearing but should be free of pits and flaking.

If hours are tracked this frequency can be adjusted for maximum motor life. The procedure can be performed in about 15 minutes. Exact directions for doing this are in the Titespot® Angle Head Operation Manual

Once the reaction ring has been flipped it should last about the same number of hours as the first side. So keep tracking hours of operation. Unfortunately it is not normally practical to try and rebuild the motor yourself as the equipment, inventory and training are cost prohibitive.

It is important once the reaction ring is worn on both ends to get the motor refreshed. By this time typically the balls will need to be replaced and the bores in the rotor honed to remove pits and round them back up. The motor can be rebuilt like this several times if it’s not allowed to become too worn. Pitted bores and flattened balls will destroy the motor in short order. It can be replaced but it is more cost effective to keep it in good shape.

Next topic: How long will my head last?