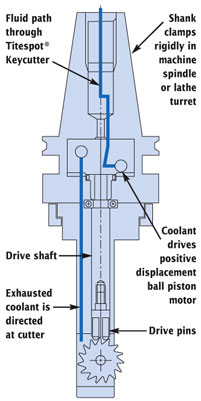

Titespot® Coolant Driven Key Cutters for Lathes & Machining Centers

Eliminate Secondary Broaching Operations on Gears, Sheaves, Hubs and Pulleys

Titespot® Coolant Driven Keycutters incorporate a positive displacement ball piston motor powered by your high pressure system (200-2000 PSI14-140 Bar depending upon the “load” of the application). The drive shaft transmits power from the motor to the arbor type stagger tooth cutter via the drive pins. Exhausted coolant is directed at the cutter interface.

Key Cutters Product Content

Titespot® Keycutters Advantages

- Machine spindle rotation not required for power.

- Spindle can be used as an indexer to machine multiple keyways with one Keycutter.

- Odd size or wide keyways can be produced by multiple passes.

- Loads easily from ATC on a machining center.

- Combines keycutting with boring or turning operations on lathe

- Effective in blind or thru bore applications.

- Gear reduction generates up to 10 ft. lbs.13 Nm of torque at 1,000 PSI70 Bar coolant pressure.

- Machines keyways and splines in bores down to 1/2″12.7 mm in diameter.