Titespot® Keycutters | Performance Data

Speed Is Based on Flow

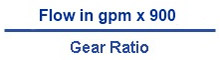

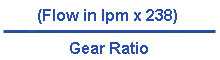

At approximately 70% volumetric efficiency the positive displacement ball piston motor will rotate at 900 RPM per GPM238 RPM per LPM.

Calculate Cutter RPM:

Example: KC02 Keycutter with Cutter #103, coolant flow

9 GPM: 9(GPM) x 900(RPM of motor per GPM flow) /30LPM: 30(LPM) x 238(RPM of motor per LPM flow) /

4.5(gear ratio of KC02) = 1800 RPM

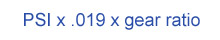

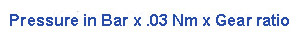

Torque Is Based on Pressure

Under test conditions, the ball piston motor develops .019 in. lbs. of torque for each PSI.03 Nm of torque for each Bar of coolant pressure.

Calculate Keycutter Torque:

Example: KC03 Keycutter with Cutter #302 at 800 PSI

coolant pressure: 800 (coolant pressure in PSI) x .019 x 5.5

(gear ratio of KC03) = 83.6 in. lbs. or 6.96 ft. lbs. of torque.

Example: KC03 Keycutter with Cutter #302 at 55 Bar

coolant pressure: 55 (coolant pressure in Bar) x .03 x 5.5

(gear ratio of KC03) = 9.07 Nm of torque.